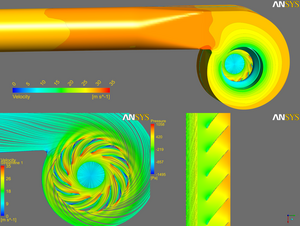

Computational Fluid Dynamics for fans and plants

In the field of turbomachinery construction, CFD has, within the space of just a few years, become an indispensable tool for the optimization and new design of turbomachines, as well as for the elimination of fluid-mechanic problems in installed systems. The following paper demonstrates the basic knowledge as well as applied examples of the CFD simulations of process fans.